Off late many batch type Tyre pyrolysis plants have started using plastic in their rotary reactors. Shifting to plastic is a good idea but not without proper consultation. Plastics are not a standard product like tyre. There are different grades and the results vary with different mix. Plastics produce much more gas as compared to tyre so the machine should be thoroughly inspected before use of plastic.

Off late many batch type Tyre pyrolysis plants have started using plastic in their rotary reactors. Shifting to plastic is a good idea but not without proper consultation. Plastics are not a standard product like tyre. There are different grades and the results vary with different mix. Plastics produce much more gas as compared to tyre so the machine should be thoroughly inspected before use of plastic.

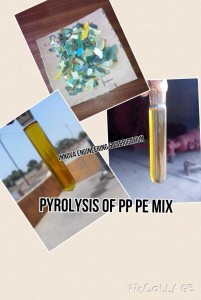

The oil quality with out catalyst is very poor with a mix of different densities and lot of wax. This wax can choke your condensers. You have to identify the right mix of catalyst that can reduce the wax formation. The catalyst can reduce the process temperature, change the oil colour to red or yellowish and produce higher yields.The design of catalyst chamber and refluxing of vapours is necessary for reduction of waxes. The lines and condensers also play a huge role in yield.

This is what a consultation can cover