Continuous or Batch Type Plastic Pyrolysis Plant

There are different types of pyrolysis plant available but can be divided in to three types.

- Continuous: You feed material on one side and remove carbon continuously from the other side

- Semi continuous: Where you fill the reactor with the raw material and take a process and then without cooling it down take out the carbon and input the second batch of raw material.

- Batch type: Here you fill the raw material with a batch of raw material and take the process. Next process will happen after cooling down and removal of carbon.

Of the above three types

- Continuous plants are very expensive and it is not viable for a small investor.

- The semi continuous type of pyrolysis plants are capable of processing up to 2-4 tons per day. Bigger capacities are not successful as of date. The machine saves lot of energy as it doesn’t have to be cooled down to add the next batch of raw material, but at the same time the power required and consumed in such plants is very high. The maintenance is complicated and need company provided technicians to attend. There is always problem with feeding and carbon removal. You need to shred the material to less than 10mm to feed properly. The material should be cleaned and cleared of metals. Lot of manpower is required to do this. These plants also have exploded on a small level. Safety is more as the batch size is low.People who have bought these pyrolysis plants on a majority have not multiplied. This indicates low profit. No reliable pyrolysis plant provided so far in the market except for some expensive ones.

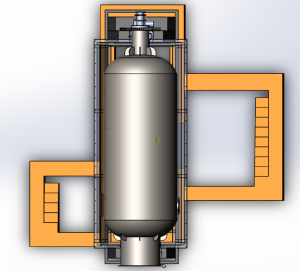

- The most popular is the batch type pyrolysis plant. This pyrolysis plants are economical and very easy to operate. These pyrolysis plants can cost from 30 lakh INR onwards for very cheap quality plants. In china the plants start at 40000 USD. Good machines will cost around 45-50 lakhs with good safety features and proper boiler quality material. Chinese machines will cost around50000 to 80000 USD excluding duties freight and taxes. The beauty of the pyrolysis plant is you don’t have to pre-process the raw material, Power consumption is very low. Any tom dick and harry can do the maintenance. It has very few parts that will need maintenance. However as simple as it looks many people are just copying the machines and fabricating the machines without any design consideration and fabrication procedure. Poor quality machines are also being imported from china. These plants can be risky if you do not know how to operate the machine and can also lead to explosions. These machines have the best ROI as it is cheaper and also you can see people multiplying the number of plants clearly indicating good profit.

- It is a myth that pyrolysis plants are very polluting. If you handle the carbon properly and do proper housekeeping of your plants it will be like any other manufacturing company. Regarding pollution control you should handle carbon properly and the exhaust gases should be burnt and scrubbed.

No matter what type you choose manufacturers should be responsible for what they are selling. Pyrolysis machine should not only generate profit for their clients but also be environmentally friendly. Use of wood should be avoided; proper pollution control equipment should be installed, provide better technology upgrades.

Avoid cheap quality plants as you might spend less now but would be left with a non-working plant high maintenance plant.