Google’s Startup for Sustainable Development Program Recently updated !

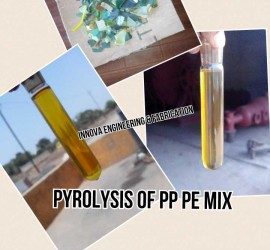

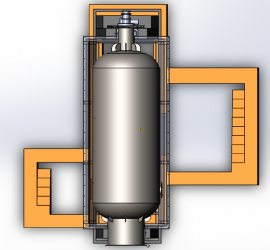

We are thrilled to announce that Goenvi Technologies, a chemical recycling company focused on sustainable waste management solutions, has been selected for Google’s Startup for Sustainable Development Program. This program is designed to support innovative startups that are working towards creating a more sustainable future. As a chemical recycling company, […]