1) Overview of pyrolysis plant

1) Overview of pyrolysis plant

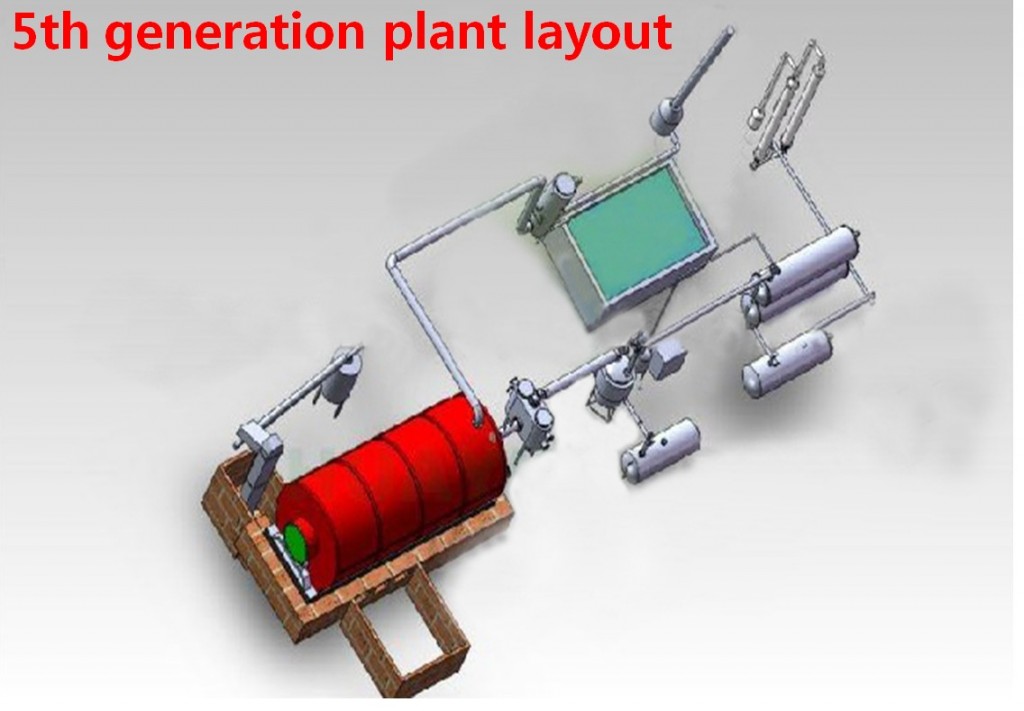

The whole pyrolysis system is composed by 13 parts, which are reactor ,transmission device, catalytic chamber, cooling tube, heavy tank ,oil-water separator, condenser, light oil tank, safety device, vacuum system, dedusting system, draft fan, chimney.

The heart of the pyrolysis plant are reactor and cooling system.

Reactor directly decides the machine’s safety and service life. It is made by welded steel plate. So the quality of welding will have a direct impact on safety and service life. Therefore, we use automatic welding machine, X-rays detection and heating treatment which will not only guarantee the quality of welding but also greatly improve working efficiency.

For cooling systems, there are two steps. Cooling pipe is the first step. The second is condenser. We have two horizontal condensers. The heat exchanging area is about 32 square meters for one condenser and also two vertical condenser in the safety device with 4 square meters each. So the total cooling area is about 70 square meters, which will guarantee you a high oil yield.

2) Main features:

Safety:

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Professional heating treatment and x-ray detection chamber are especially for welding.

3. Vacuum system will prevent oil gas from going back to reactor and causing accident.

4. Professional thermometer, pressure gauge and safety valve.

5. It is dangerous to burn exhaust gas (C1 to C4) without any safety measures. In our process, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Environment friendly:

1. Well water dedusting system can avoid black smoke.

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Every junction of the reactor is in good sealing situation with professional sealing material.

Long service life:

1. Material: Q345R special steel plate, thickness 16mm

2. Welding: Automatic welding machine with heat treatment and x-ray detection will prolong the service life of reactor to the max.

3. The service life of the reactor will be approximately 8 years

Energy saving:

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

3)Salient features:

1) Safety: OUR tire pyrolysis plant is equipped with many safety measures such as pressure gauge, safety valve and alarming devices. If there is extra pressure inside the reactor, alarming system will ring, if no worker hear this, do not worry, the safety valve will automatically release pressure. Besides oil-water separator and anti-back fire device stop the waste gas back into reactor so that we avoid the possibility danger of explosion.

2) Higher oil yield rate: OUR tire pyrolysis plant adopted the most advanced independent cooling system. We concentrate on decreasing the cooling time and increase cooling area so that we can cool more oil gas and get more oil. Besides we use catalyst when we pyrolysis tire, so that we can make fully pyrolysis for tires and increase make full use of the tire materials and make good quality oil. At same time with our 20 years experience of making tire oil, our engineer can transfer our best operation skills which how can make more oil.

3)Environmental friendly : OUR tire pyrolysis plant have a whole set of carbon black discharging system which can collect the carbon black under the sealing condition it is very clear. After collecting carbon black into bags, we can use carbon black fuel machine to turn the carbon black into fuel then u can make money from carbon black. Besides smoke from burning coal or wood can be filtered by our dust removing system, draught fan and cooling chimney will further remove the dust. At last emission from chimney no color no smelling and no pollution.

4) Energy saving: OUR tire pyrolysis plant is equipped with waste gas (methane, ethane, propane, hydrogen etc) recycling system, which can recycle the gas back into the furnace to heat reactor. Fuel is also a cost for customers, this system can save customers’ cost at same time we protect our environment.

5) Fully Automatic: OUR tire recycling plant is fully automatic. Our plant is equipped with auto-feeder, which can put 10 ton tires into reactor with 2-3 hours instead of manpower loading with 6-7 hours. From feeding to discharging all the process is automatic. We called “Idiot Plant”, it means our plant is very easy to operate, as it is very highly automatic. If you want to know more about our plant please send us inquiry, we will offer more details.

6) After-sales service: After purchasing our plant, we would send our engineer to instruct your workers to install your plant at the same time training your workers on how to operate the plant correctly. Each of our engineer from our company has many years experience of installation and making tire oil. Operating plant correctly decides tire oil yield rate directly and your workers’ safety.

4) Technical parameter

|

Technical parameter of our Pyrolysis Equipment |

||||

|

Items |

Contents |

|||

|

1 |

Equipment type |

IE-6 |

IE-8 |

IE-10 |

|

2 |

Raw material |

tires/Plastic |

tires/Plastic |

tires/Plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7ton |

3.6 ton |

4.5 ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of Reactor |

Q345R |

Q345R |

Q345R |

|

8 |

Thickness of Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of Reactor |

0.8turn/minute |

0.8turn/minute |

0.8turn/minute |

|

10 |

Total power |

12KW |

15KW |

20.2KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

40sqm |

50sqm |

70sqm |

|

14 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

16 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

17 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

18 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

19 |

Delivery time |

15days |

15days |

15days |

|

20 |

Weight |

25T |

28T |

32T |