Vertical condenser: 4th Generation Equipment Design

Vertical condenser: 4th Generation Equipment Design

length of pipe 1.5m, diameter of pipe 32mm, 57 pipes in each condenser,

Cooling area= 3.14*0.032*1.5*57=8.59 sq.meter

5 vertical condensers cooling area is 42.95 sq.meter.

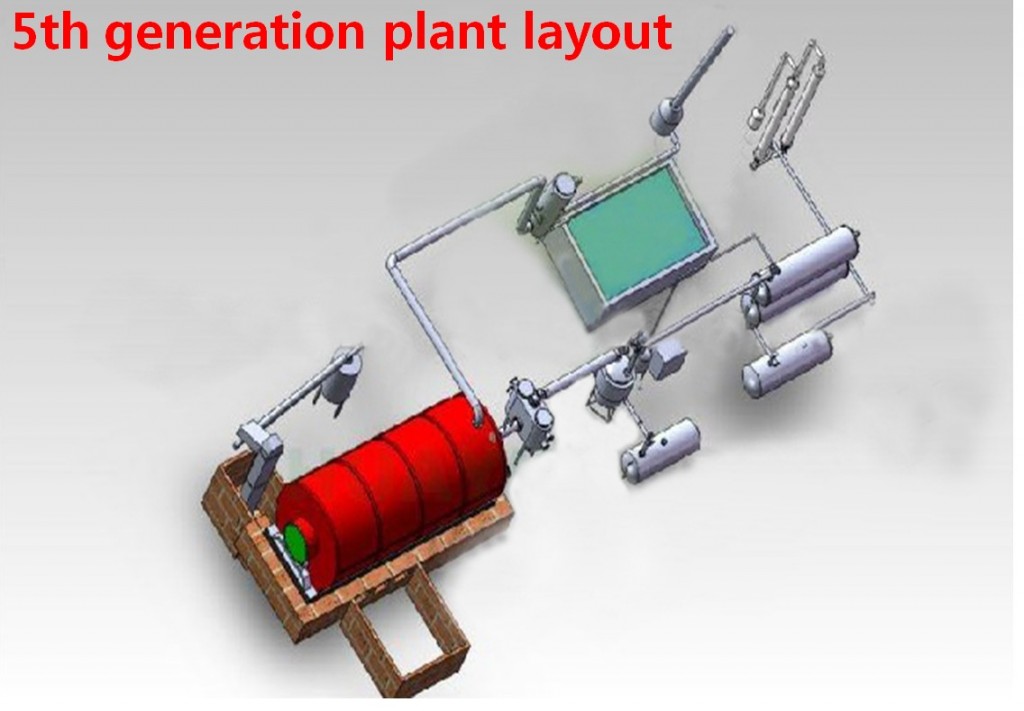

Horizontal condenser: 5th Generation Design

length of pipe 3m, diameter of pipe 48mm, 69 pipes in each.

Cooling area= 3.14*0.048*3*69=31.19 sq.meter

2 horizontal condenser cooling area is 62.38 sq.meter,

5th generation machine has waste gas recycling device, it has extra 2 condensers, diameter of pipe is 48mm, length is 3m.

Cooling area is 3.14*0.048*3*9*2=8.14 sq.meter.

So total cooling area is 70.52 sq.meter.

From here we can see the cooling area of the 5th is much bigger than the 4th, so the oil rate is more.